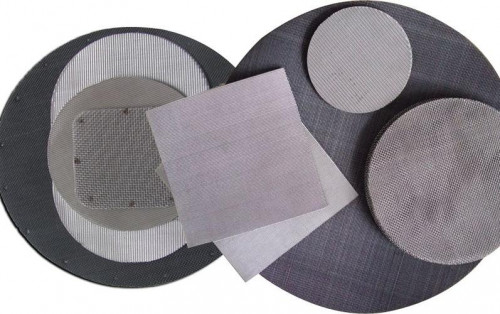

Wire filters are used to prevent particles or debris from entering a system or equipment through wires or cables. They are typically made of fine mesh screens or mesh pads and are placed at the entrance or exit points of the wire or cable to ensure that only clean air or fluids pass through.

Wire filters are commonly used in various industries and applications, including HVAC systems, ventilation systems, water and wastewater treatment plants, oil and gas refineries, food and beverage processing, pharmaceutical manufacturing, and more. They can help protect equipment from damage, improve system efficiency, and ensure the quality and cleanliness of fluids or air.

The mesh size or porosity of wire filters can vary depending on the specific application and the size of particles or debris that need to be filtered out. They can be made from various materials such as stainless steel, brass, bronze, or synthetic fibers, and their design and construction can vary based on the operating conditions and requirements of the system.

Wire filters are relatively easy to install and maintain, as they can be easily removed and cleaned or replaced when they become clogged or dirty. Regular maintenance and cleaning of wire filters are important to prevent pressure drops, maintain system performance, and prolong the lifespan of the filters and the equipment they protect.

ensuring the proper functioning and longevity of systems and equipment by effectively filtering out particles and debris that could cause damage or reduce system performance.

DEZE FIltration is a leading Manufacturer of Wire filters from ???, China.

Read MoreWire filters are used to prevent particles or debris from entering a system or equipment through wires or cables. They are typically made of fine mesh screens or mesh pads and are placed at the entrance or exit points of the wire or cable to ensure that only clean air or fluids pass through.

Wire filters are commonly used in various industries and applications, including HVAC systems, ventilation systems, water and wastewater treatment plants, oil and gas refineries, food and beverage processing, pharmaceutical manufacturing, and more. They can help protect equipment from damage, improve system efficiency, and ensure the quality and cleanliness of fluids or air.

The mesh size or porosity of wire filters can vary depending on the specific application and the size of particles or debris that need to be filtered out. They can be made from various materials such as stainless steel, brass, bronze, or synthetic fibers, and their design and construction can vary based on the operating conditions and requirements of the system.

Wire filters are relatively easy to install and maintain, as they can be easily removed and cleaned or replaced when they become clogged or dirty. Regular maintenance and cleaning of wire filters are important to prevent pressure drops, maintain system performance, and prolong the lifespan of the filters and the equipment they protect.

ensuring the proper functioning and longevity of systems and equipment by effectively filtering out particles and debris that could cause damage or reduce system performance.

Wire filters are used to prevent particles or debris from entering a system or equipment through wires or cables. They are typically made of fine mesh screens or mesh pads and are placed at the entrance or exit points of the wire or cable to ensure that only clean air or fluids pass through.

Wire filters are used to prevent particles or debris from entering a system or equipment through wires or cables. They are typically made of fine mesh screens or mesh pads and are placed at the entrance or exit points of the wire or cable to ensure that only clean air or fluids pass through.

Wire filters are commonly used in various industries and applications, including HVAC systems, ventilation systems, water and wastewater treatment plants, oil and gas refineries, food and beverage processing, pharmaceutical manufacturing, and more. They can help protect equipment from damage, improve system efficiency, and ensure the quality and cleanliness of fluids or air.

The mesh size or porosity of wire filters can vary depending on the specific application and the size of particles or debris that need to be filtered out. They can be made from various materials such as stainless steel, brass, bronze, or synthetic fibers, and their design and construction can vary based on the operating conditions and requirements of the system.

Wire filters are relatively easy to install and maintain, as they can be easily removed and cleaned or replaced when they become clogged or dirty. Regular maintenance and cleaning of wire filters are important to prevent pressure drops, maintain system performance, and prolong the lifespan of the filters and the equipment they protect.

ensuring the proper functioning and longevity of systems and equipment by effectively filtering out particles and debris that could cause damage or reduce system performance.

To: DEZE FIltration

DEZE FIltration

Tell us more about your requirements so that we can connect you to the right service provider.

An easy way to post your sourcing requests and get quotes. One request, multiple quotes

Will connect you with best sellers & provide you best quotation. Verified suppliers matching. Quotes comparison and sample request

Your local business too needs brand management and image making. As you know the local market..

Send your enquiry to this supplier