| Alloy Tool Steel Drill Rod CR-V Alloy Silversteel |

115 Cr V3

Steel Nr. 1.2210

| Properties Cr-V-alloyed tool steel with high strength Maintains blade sharpness Good machinability when spheroidized-annealed Small distortion on oil hardening (possible up to approx. 9mm) |

Chemical Analysis | ||

|---|---|---|---|

| C | 1.15% | ||

| Cr | 0.70% | ||

| V | 0.10% | ||

| Si | 0.25% | ||

| Mn | 0.30% | ||

| Examples of Applications Twist drills and thread taps, reamers, piercing dies, ejectors, arbors, engraving tools, scrapers, files, etc.Is preferably used with silver steel finish in smallest tolerances |

|||

| Delivery Conditions Spheroidized-annealed, drawn, ground and polished |

Annealed tensile strength Max 750 N/mm2 (220HB) |

||

| Heat Treatment | |

|---|---|

| Hot Shaping -> | 1050-850 degrees C |

| Soft Annealing Temperature -> | 710-750 degrees C |

| Hardening Temperature -> | 810-840 degrees C in oil |

| 780-810 degrees C in water | |

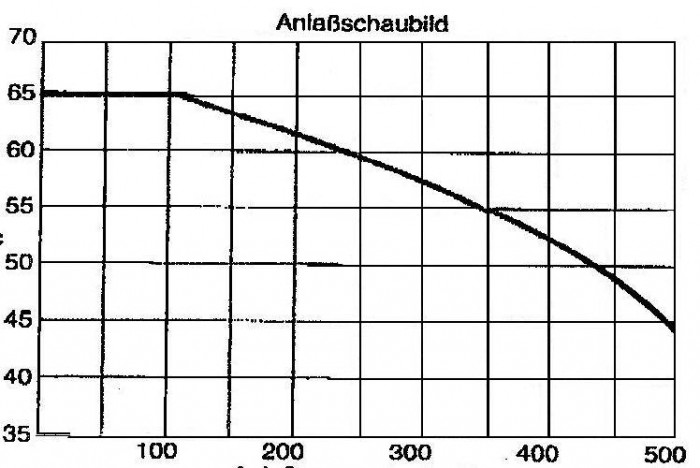

| Hardness in HRC | Annealing Temperature in degrees Celsius | |

|---|---|---|

| Nomimal Dimension | Tolerance Zone in mm (external measurements) | ||

|---|---|---|---|

| Over | To | h8 (Steel) | |

| 0 | 1 | 0 | -0.014 |

| 1 | 3 | 0 | -0.014 |

| 3 | 6 | 0 | -0.018 |

| 6 | 10 | 0 | -0.022 |

| 10 | 18 | 0 | -0.027 |

| 18 | 30 | 0 | -0.033 |

| Nomimal Dimension | Tolerance Zone in mm (external measurements) | ||

|---|---|---|---|

| Over | To | h9 (Stainless Steel) | |

| 1 | 3 | 0 | -0.025 |

| 3 | 6 | 0 | -0.030 |

| 6 | 10 | 0 | -0.036 |

| 10 | 18 | 0 | -0.043 |

| 18 | 30 | 0 | -0.052 |

| DIN 175-h8 Steel | DIN 671-h9 Stainless Steel |

All information is strictly informative