![]() Shanghai, China

Shanghai, China

GSTIN : WSS manufactures mainly super-hard tools, such as

GSTIN : WSS manufactures mainly super-hard tools, such as

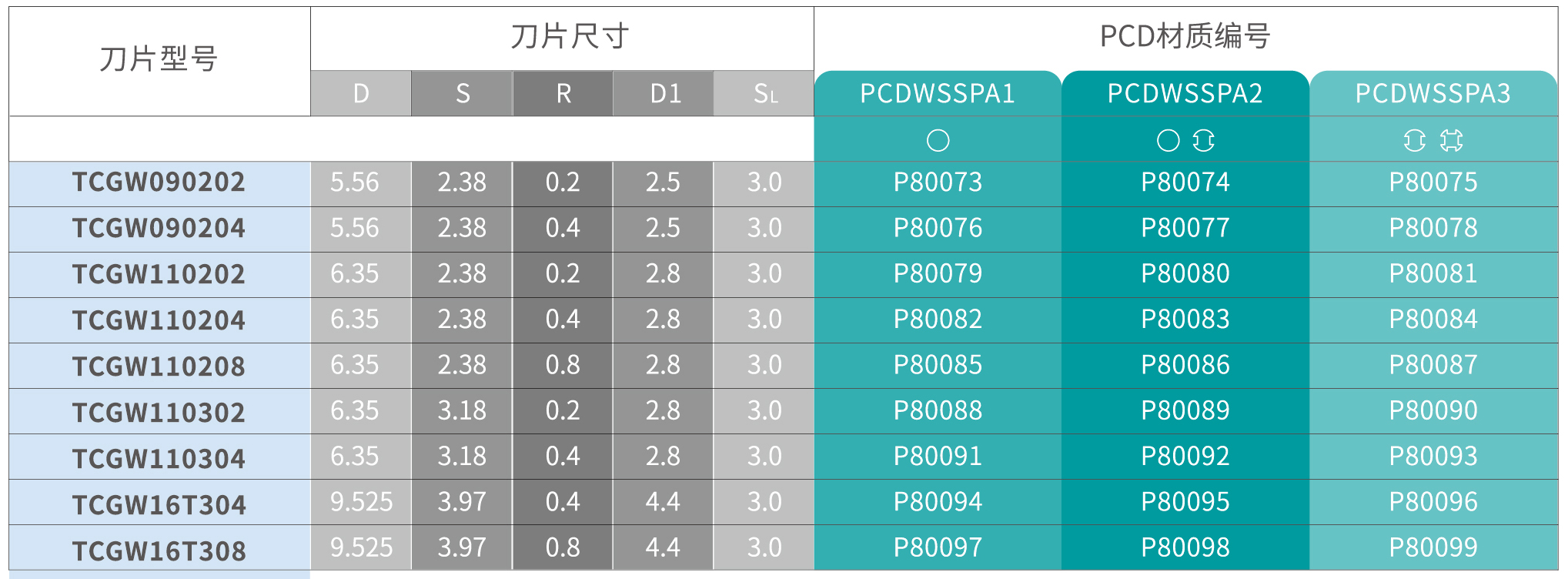

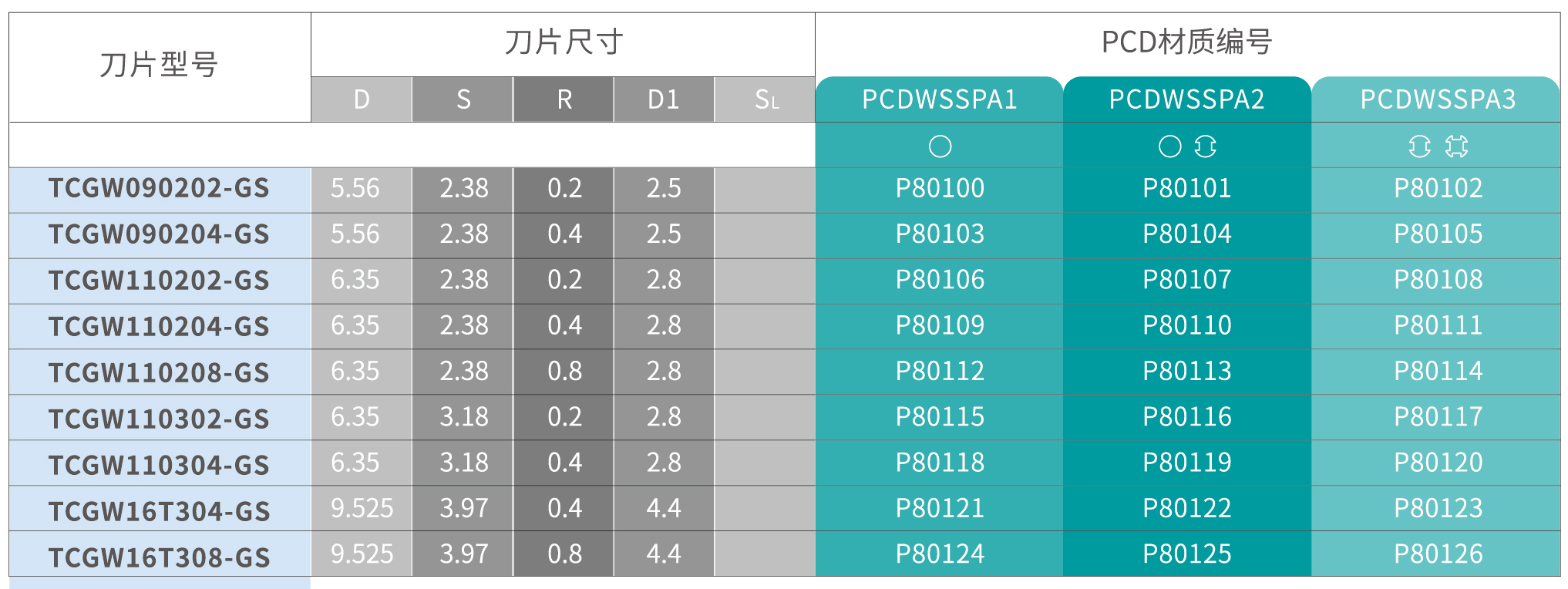

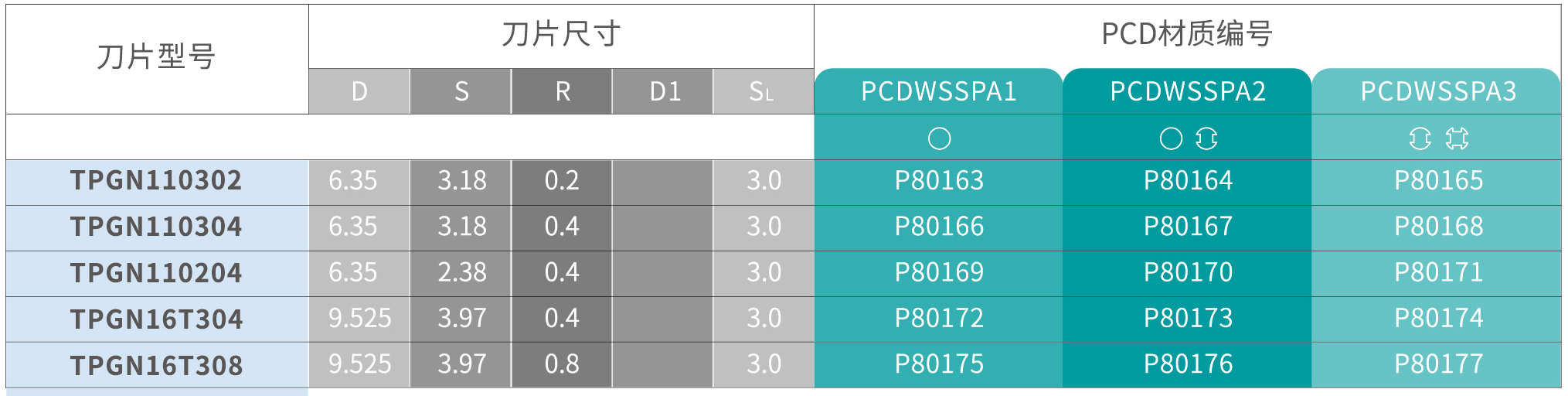

Efficient based on continuous improvement of professional work PCD consists of 99.9% carbon isotope C12. Its high thermal conductivity is 50% better than natural diamond and 2 times faster than copper. PCD property provides wear resistance up to 500 times that of conventional carbide. Polycrystalline diamond can be sintered to cemented carbide substrate through special high temperature and pressure process. PCD insert is the best for machining non-ferrous metals and non-metal. It has replaced tungsten carbide and ceramics in a range of high speed performance applications including the turning, boring, milling, slotting and chamfering of materials such as high-silicon aluminum, metal matrix composites (MMC), ceramics, reinforced epoxies, plastics, carbon-fibre-reinforced plastics (CFRP) and engineered wood products. The extended tool life and increased productivity provide by PCD tools offer cost effective solutions for many applications

CBN blanks are manufactured from cubic boron nitride crystals utilizing an advanced high temperature, high-pressure process. The cubic boron nitride crystals are sintered together with a binder phase and integrally bonded to a tungsten carbide substrate. The binder phase, usually either a metallic or ceramic matrix, provides chemical stability, enabling the CBN qualities to be utilized in high-speed machining environment. The substrate in the CBN blanks provides the high impact resistance necessary for the depth of cuts and high speed associated with machining of hardened ferrous materials. CBN cutting tools offer excellent heat dissipation and wear resistance. Cutting tool geometries can be prepared to withstand interrupted cut. CBN tools offer the following benefit: (a) machine-hardness and heat-treated steels, (b) an excellent surface finish that allow eliminated grinding, (c) high productivity rate that can be more than four times higher than that in grinding, (d) grat resistance to abrasion which is twice that ceramics and ten times than that of carbide. CBN tools are recommended for machining cast iron including compacted graphite iron (CGI), sintered iron and super alloys hardened steel.

Efficient based on continuous improvement of professional work PCD consists of 99.9% carbon isotope C12. Its high thermal conductivity is 50% better than natural diamond and 2 times faster than copper. PCD property provides wear resistance up to 500 times that of conventional carbide. Polycrystalline diamond can be sintered to cemented carbide substrate through special high temperature and pressure process. PCD insert is the best for machining non-ferrous metals and non-metal. It has replaced tungsten carbide and ceramics in a range of high speed performance applications including the turning, boring, milling, slotting and chamfering of materials such as high-silicon aluminum, metal matrix composites (MMC), ceramics, reinforced epoxies, plastics, carbon-fibre-reinforced plastics (CFRP) and engineered wood products. The extended tool life and increased productivity provide by PCD tools offer cost effective solutions for many applications.

Efficient based on continuous improvement of professional work PCD consists of 99.9% carbon isotope C12. Its high thermal conductivity is 50% better than natural diamond and 2 times faster than copper. PCD property provides wear resistance up to 500 times that of conventional carbide. Polycrystalline diamond can be sintered to cemented carbide substrate through special high temperature and pressure process. PCD insert is the best for machining non-ferrous metals and non-metal. It has replaced tungsten carbide and ceramics in a range of high speed performance applications including the turning, boring, milling, slotting and chamfering of materials such as high-silicon aluminum, metal matrix composites (MMC), ceramics, reinforced epoxies, plastics, carbon-fibre-reinforced plastics (CFRP) and engineered wood products. The extended tool life and increased productivity provide by PCD tools offer cost effective solutions for many applications.

Efficient based on continuous improvement of professional work PCD consists of 99.9% carbon isotope C12. Its high thermal conductivity is 50% better than natural diamond and 2 times faster than copper. PCD property provides wear resistance up to 500 times that of conventional carbide. Polycrystalline diamond can be sintered to cemented carbide substrate through special high temperature and pressure process. PCD insert is the best for machining non-ferrous metals and non-metal. It has replaced tungsten carbide and ceramics in a range of high speed performance applications including the turning, boring, milling, slotting and chamfering of materials such as high-silicon aluminum, metal matrix composites (MMC), ceramics, reinforced epoxies, plastics, carbon-fibre-reinforced plastics (CFRP) and engineered wood products. The extended tool life and increased productivity provide by PCD tools offer cost effective solutions for many applications.

Efficient based on continuous improvement of professional work PCD consists of 99.9% carbon isotope C12. Its high thermal conductivity is 50% better than natural diamond and 2 times faster than copper. PCD property provides wear resistance up to 500 times that of conventional carbide. Polycrystalline diamond can be sintered to cemented carbide substrate through special high temperature and pressure process. PCD insert is the best for machining non-ferrous metals and non-metal. It has replaced tungsten carbide and ceramics in a range of high speed performance applications including the turning, boring, milling, slotting and chamfering of materials such as high-silicon aluminum, metal matrix composites (MMC), ceramics, reinforced epoxies, plastics, carbon-fibre-reinforced plastics (CFRP) and engineered wood products. The extended tool life and increased productivity provide by PCD tools offer cost effective solutions for many applications.

Efficient based on continuous improvement of professional work PCD consists of 99.9% carbon isotope C12. Its high thermal conductivity is 50% better than natural diamond and 2 times faster than copper. PCD property provides wear resistance up to 500 times that of conventional carbide. Polycrystalline diamond can be sintered to cemented carbide substrate through special high temperature and pressure process. PCD insert is the best for machining non-ferrous metals and non-metal. It has replaced tungsten carbide and ceramics in a range of high speed performance applications including the turning, boring, milling, slotting and chamfering of materials such as high-silicon aluminum, metal matrix composites (MMC), ceramics, reinforced epoxies, plastics, carbon-fibre-reinforced plastics (CFRP) and engineered wood products. The extended tool life and increased productivity provide by PCD tools offer cost effective solutions for many applications.

Tell us more about your requirements so that we can connect you to the right service provider.

An easy way to post your sourcing requests and get quotes. One request, multiple quotes

Will connect you with best sellers & provide you best quotation. Verified suppliers matching. Quotes comparison and sample request

Your local business too needs brand management and image making. As you know the local market..

No. 176, Jingche Road, Songjiang District (Chedun), CN-201611 Shanghai, P.R. China, Shanghai - Shanghai,

Shanghai, China.

wssprecisiontools (Marketing Department)

Requirement