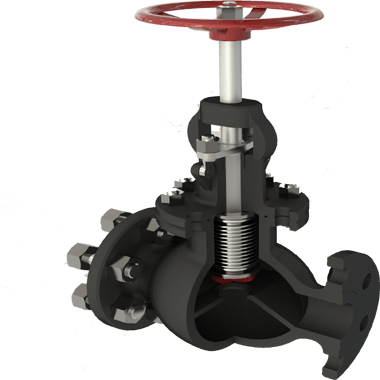

Bellow sealed valves are a new type of Industrial Process valves. These valves are popular due to the leakage free performance hence, called “Zero Leak Valves” or “Emission Free Valves”.

With the application of Bellow seals the gland packing is supplemented by a metallic Bellow cartridge. One end of the Bellow is connected to the valve bonnet and the other end to the stem. The bellow movement is in one plane as the stroke in the valve takes place. With no rotational movements involved the fluid gets sealed to a very high degree. The fluid flows through the bottom part of the valve as per the stem movement takes place. Due to the bellow covering the stem the seal does not contact the stem at all. As the stem is the moving part in the valve it is the source of leakage due to the wear and tear of gland packing. Due to this shielding of the stem by the bellow the valve operated in a leak free zone.

The life cycle of the valve Bellows is largely dependent on the process of bellow manufacturing. At Pliant Bellows we manufacture them by hydroforming process. The properties achieved by the hydro forming process are far superior as compared to other process like, diaphragm welded bellows or mechanically drawn bellows. It is extremely important that the valve bellows have the mechanical and metallurgical properties for long cycle life of an bellow to avoid

Pliant Bellows ( Kwality Products ) is a leading Manufacturer of Valve Bellows from Pune, India.

Read More

Bellow sealed valves are a new type of Industrial Process valves. These valves are popular due to the leakage free performance hence, called “Zero Leak Valves” or “Emission Free Valves”.

With the application of Bellow seals the gland packing is supplemented by a metallic Bellow cartridge. One end of the Bellow is connected to the valve bonnet and the other end to the stem. The bellow movement is in one plane as the stroke in the valve takes place. With no rotational movements involved the fluid gets sealed to a very high degree. The fluid flows through the bottom part of the valve as per the stem movement takes place. Due to the bellow covering the stem the seal does not contact the stem at all. As the stem is the moving part in the valve it is the source of leakage due to the wear and tear of gland packing. Due to this shielding of the stem by the bellow the valve operated in a leak free zone.

The life cycle of the valve Bellows is largely dependent on the process of bellow manufacturing. At Pliant Bellows we manufacture them by hydroforming process. The properties achieved by the hydro forming process are far superior as compared to other process like, diaphragm welded bellows or mechanically drawn bellows. It is extremely important that the valve bellows have the mechanical and metallurgical properties for long cycle life of an bellow to avoid

Valve Bellows

Bellow sealed valves are a new type of Industrial Process valves. These valves are popular due to the leakage free performance hence, called “Zero Leak Valves” or “Emission Free Valves”.

With the application of Bellow seals the gland packing is supplemented by a metallic Bellow cartridge. One end of the Bellow is connected to the valve bonnet and the other end to the stem. The bellow movement is in one plane as the stroke in the valve takes place. With no rotational movements involved the fluid gets sealed to a very high degree. The fluid flows through the bottom part of the valve as per the stem movement takes place. Due to the bellow covering the stem the seal does not contact the stem at all. As the stem is the moving part in the valve it is the source of leakage due to the wear and tear of gland packing. Due to this shielding of the stem by the bellow the valve operated in a leak free zone.

The life cycle of the valve Bellows is largely dependent on the process of bellow manufacturing. At Pliant Bellows we manufacture them by hydroforming process. The properties achieved by the hydro forming process are far superior as compared to other process like, diaphragm welded bellows or mechanically drawn bellows. It is extremely important that the valve bellows have the mechanical and metallurgical properties for long cycle life of an bellow to avoid

Kwality Products From Pune Maharashtra established in 1975, exclusively with a prime objective to manufacture world-class Expansion Bellows, Bellow Couplings & Metal Bellows manufacturer in India with the brand name Pliant Bellows, has now become a globally accepted provider of flexible piping systems exporting to more than 40 countries with a wide installation base covering almost all industrial sectors including and diverse as nuclear power and space programs. Our adherence to the highest standards of quality and precision makes us experts in Flexible Piping Systems. Supporting this dedication to quality is our ISO-9001:2015 certified system for designing, manufacturing, and testing armed and equipped with the latest state-of-the-art technology. The majority of our Expansion Bellows, Expansion Joints and Metal Bellows products are customized solutions. It means that we design and produce pipe expansion joints or metal expansion joints in accordance with close interaction with the customer requirements. Furthermore, we are often involved with our customers in the design and development of new products for challenging applications.

All major industrialized manufacturing processes that require piping and changes in temperature trust upon our expansion bellows or Metal Bellows products and services, Petro Chemical, Power generation, Fuel Cell Power Systems, Electrical Distribution Market, Industrial Gases, Chemical Processing, Oil and Gas Distribution, Utility piping, Solar Technology, Steel, Cement, Shipbuilding to name a few. Under the guidelines of standards, Pliant Bellows offers a complete range of metal expansion joints with the ability to design joints to every individual customers requirements. Pliant bellows expansion joints carry additional safety factors to ensure the long fatigue life of Metal expansion bellows. Though we offer a wide range of flexible components, were especially proud of our Metal Bellows Expansion joints. These metallic bellows expansion joints and allied products enjoy high recommendations from our global. Design calculations are performed using design software developed in-house and calculations are further checked using hand calculations.

To: Pliant Bellows ( Kwality Products )

Pliant Bellows ( Kwality Products )

Anand Uttarkar

Final plot no.38/1 Ramtekdi Industrial Estate Hadapsar, Pune - 411013, India

LOGIN AND GET CONTACT DETAILS.

Tell us more about your requirements so that we can connect you to the right service provider.

An easy way to post your sourcing requests and get quotes. One request, multiple quotes

Will connect you with best sellers & provide you best quotation. Verified suppliers matching. Quotes comparison and sample request

Your local business too needs brand management and image making. As you know the local market..

Send your enquiry to this supplier